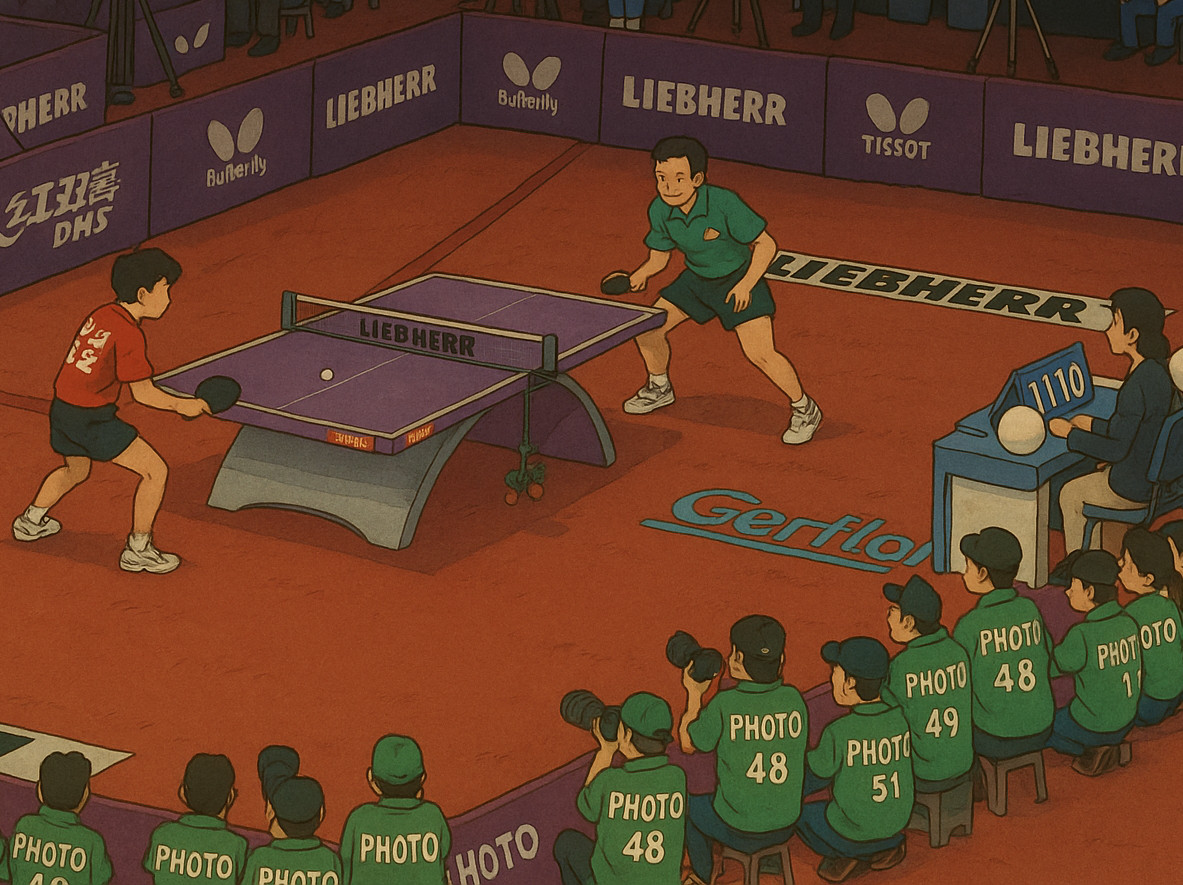

How to Build a Concrete and Rebar Table Tennis Table

Building a permanent outdoor table tennis table from concrete and rebar creates a durable, weather-resistant playing surface that will last for decades. This guide will walk you through the process of creating a wooden frame mold and pouring a regulation-size concrete table.

Table Specifications

- Dimensions: 9 feet long × 5 feet wide (2.74m × 1.525m)

- Height: 30 inches (76cm) from ground to playing surface

- Thickness: 3-4 inches (7.6-10cm) of concrete

- Net Height: 6 inches (15.25cm) at center

Materials Needed

For the Wooden Frame (Mold):

- 2×4 lumber: approximately 40 linear feet for frame sides

- 3/4" plywood: two 4'×8' sheets for the base

- Wood screws: 3" deck screws

- Release agent or cooking oil (to prevent concrete from sticking)

- Level

- Saw (circular or hand saw)

- Drill with bits

For the Concrete Table:

- #4 rebar (1/2" diameter): approximately 20 pieces at 9 feet long, 10 pieces at 5 feet long

- Rebar ties or wire

- Concrete mix: approximately 50-60 bags of 80lb concrete mix (or 1.5-2 cubic yards ready-mix)

- Concrete reinforcement mesh (optional, for extra strength)

- Concrete sealer and/or table tennis table paint

- Cinder blocks or concrete piers for support (8-12 blocks)

- Sand for leveling base

Important Tips

- Weather: Pour concrete when temperatures are between 50-80°F and no rain is forecasted for 24 hours

- Level is Critical: Check level multiple times during frame construction and concrete pour

- Reinforcement: Don't skip the rebar - it prevents cracking and adds crucial strength

- Sealing: Seal the concrete to protect against moisture and weathering

- Safety: Wear gloves when working with concrete (it's caustic) and safety glasses

- Help: This is a heavy project - recruit 2-3 helpers for the pour

Maintenance

- Clean the surface regularly with a broom and water

- Reapply sealer every 2-3 years

- Touch up paint and lines as needed

- Inspect for cracks and repair with concrete patching compound

Step-by-Step Instructions

Step 1: Prepare the Foundation

- Select a level location with good drainage

- Clear the area of debris, grass, and roots

- Arrange 8-12 cinder blocks or concrete piers in a grid pattern (one in each corner, plus 4-6 in the middle)

- Use a level to ensure all blocks are at the same height (30 inches from ground)

- Add or remove sand beneath blocks as needed to achieve level

Step 2: Build the Wooden Form Frame

Example of a wooden frame structure for concrete forming

- Cut the plywood sheets to create a 9' × 5' base (you'll need to join two sections)

- Place the plywood on top of the cinder blocks/piers to create the bottom of your mold

- Cut 2×4 lumber for the sides:

- Two pieces at 9 feet (long sides)

- Two pieces at 5 feet (short sides)

- Stand the 2×4s on edge around the perimeter of the plywood base

- Screw the 2×4 frame pieces together at the corners

- Screw the frame to the plywood base every 12 inches

- Add vertical support braces on the outside every 2-3 feet to prevent bowing

- Coat the inside of the frame with release agent or cooking oil

Step 3: Install the Rebar Grid

Rebar grid provides structural reinforcement for the concrete

- Create a rebar grid with 12-inch spacing:

- Lay down 10 pieces of 9-foot rebar lengthwise, spaced 6 inches apart

- Lay down 10 pieces of 5-foot rebar crosswise, spaced 12 inches apart

- Use rebar ties or wire to secure all intersection points

- Elevate the rebar grid 1.5-2 inches above the plywood using small concrete spacers or rebar chairs

- Ensure the rebar is centered in what will be the thickness of the concrete

Step 4: Mix and Pour the Concrete

Carefully pour and spread the concrete mixture

- Mix concrete according to manufacturer's instructions (or have ready-mix delivered)

- Begin pouring concrete into one end of the frame

- Work the concrete around the rebar with a shovel or rake

- Fill the frame to the top edge of the 2×4s (3.5 inches thick)

- Tap the sides of the frame to release air bubbles

- Use a straight 2×4 as a screed board to level the surface by dragging it across the top of the frame

Step 5: Finish and Smooth the Surface

- After screeding, use a bull float or hand float to smooth the surface

- Work in long, sweeping motions

- For the net divider, place a 2×6 board vertically across the center while concrete is still wet

- Let the surface set for 30-60 minutes until water sheen disappears

- Perform final smoothing with a steel trowel

- For a slightly textured surface (better for play), use a broom finish after troweling

Step 6: Cure the Concrete

- Cover the concrete with plastic sheeting or wet burlap

- Keep the surface moist for 7 days

- Mist with water 2-3 times daily if using burlap

- Avoid walking on the surface for at least 3 days

- Allow to cure for a minimum of 7 days before removing forms

Step 7: Remove the Forms and Finish

The finished table ready for painting and play

- After 7 days, carefully remove the screws and dismantle the wooden frame

- Allow concrete to cure for an additional 21 days (28 days total) before painting

- Sand any rough edges smooth

- Clean the surface thoroughly

- Apply concrete sealer if desired

- Paint with dark green or blue table tennis table paint

- Mark the white boundary lines (3/4" wide) and center line using tape and white paint

- Install a permanent or removable net system at the center